By Rob Huttinga, 14 april 2021

The life cycle analysis of the BE O bottle

At BE O Lifestyle we devise and make our products with the starting point to have as little impact as possible on the environment. For our BE O bottle, this starts with the sugar cane plant and ends with the bottle in your hand. The BE O Bottle is an innovative water bottle when it comes to limiting the environmental impact. We regularly have it validated whether our BE O bottle is still doing well for the environment. Our latest life cycle analysis (LCA) by Luuk van Dijk of Radboud University shows that at the end of the line our BE O bottle absorbs CO2 and does not emit it! In this analysis we explain exactly how this is possible and what the impact would be of a BE O bottle made of traditional plastics.

Absorption of CO2

During the entire production process of the BE O bottle, from the growth of the sugar cane plant in Brazil to the assembly of the bottle in the Netherlands, more CO2 is absorbed than emitted. But what exactly does that mean? This was investigated in the LCA study. The aspects of the production process where CO2 is emitted are contrasted with the aspects in which CO2 is absorbed. When producing the BE O bottle;

CO2 is emitted by:

- Growing sugar cane

- Harvesting sugar cane

- Emissions from all types of transport

- Emissions from burning unusable waste

- Converting the sugar cane plant into material for the bottle

Co2 is absorbed by:

- The sugar cane plant and its lifespan where CO2 is converted into oxygen.

and CO2 emissions are prevented by:

- Generating electricity by burning unusable waste instead of obtaining it from another CO2 emitting source

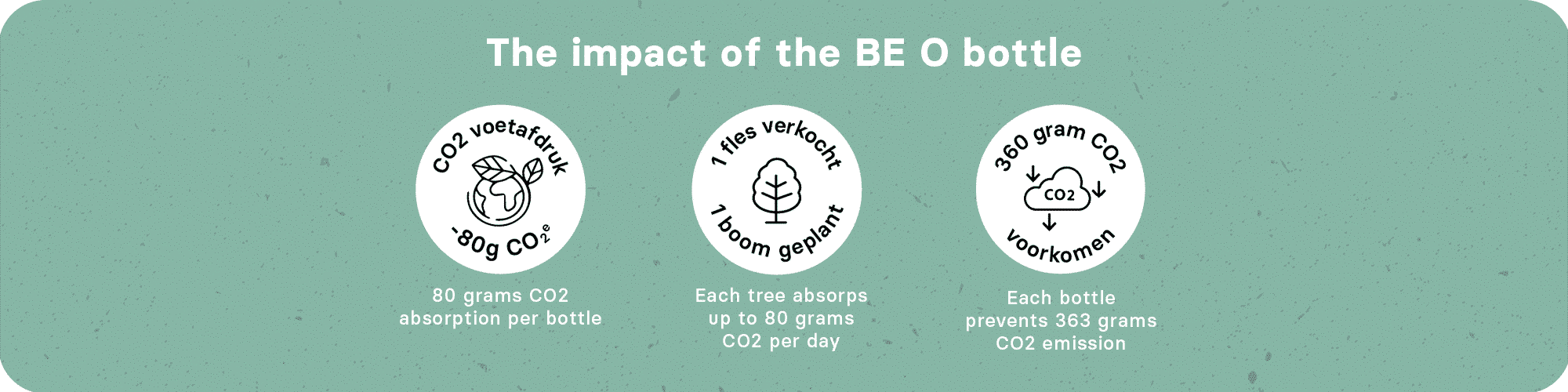

For all these aspects, it has been calculated what the CO2 emission or absorption actually is per produced bottle. Subsequently, by subtracting the total CO2 emissions per bottle from the total CO2 absorption per bottle, you have a net CO2 emission per bottle. With the BE O bottle this results in a net CO2 emission of -0.0796 kg CO2. A negative number. And that means a positive impact on the environment because, rounded off, 80 grams of CO2 is absorbed per bottle. Curious about how sugar cane is converted into bioplastic for our BE O bottle? Read it here.

What if… the BE O bottle is made from petroleum?

Difference in net CO2 emissions

Then this story would be very different. Because the material that is used does not come from the sugar cane plant, the largest factor for the absorption of CO2 during the production process is gone. And that factor is the sugar cane plant that absorbs CO2 during its lifespan and converts it into oxygen. In addition, extracting petroleum, transporting petroleum and converting petroleum into plastic are all additional aspects where CO2 is emitted. Where one BE O bottle of sugarcane absorbs 0.0796 kg CO2, one BE O bottle of petroleum would emit 0.363 kg CO2. In easier terms; From 80 grams of CO2 absorption to a significant 360 grams of CO2 emission per bottle. A difference of 440 grams of CO2 per bottle!

Difference in petroleum usage

With the BE O bottle of sugar cane, an appeal is not only made on CO2 emissions, but also on the use of petroleum. For one BE O bottle of sugar cane, 52.2 grams of petroleum are used, due to aspects such as harvesting and transport. For one BE O bottle of petroleum, 233 grams of petroleum would be used.

But it doesn't end here ...

The whole life cycle analysis does not include the fact that a tree is planted for every BE O bottle sold. This means an even more positive impact on the environment. An average tree absorbs between 50 and 80 grams of CO2 per day. In the context of transparency and fairness towards people and the environment, we have made the research accessible to everyone. Consult it here!