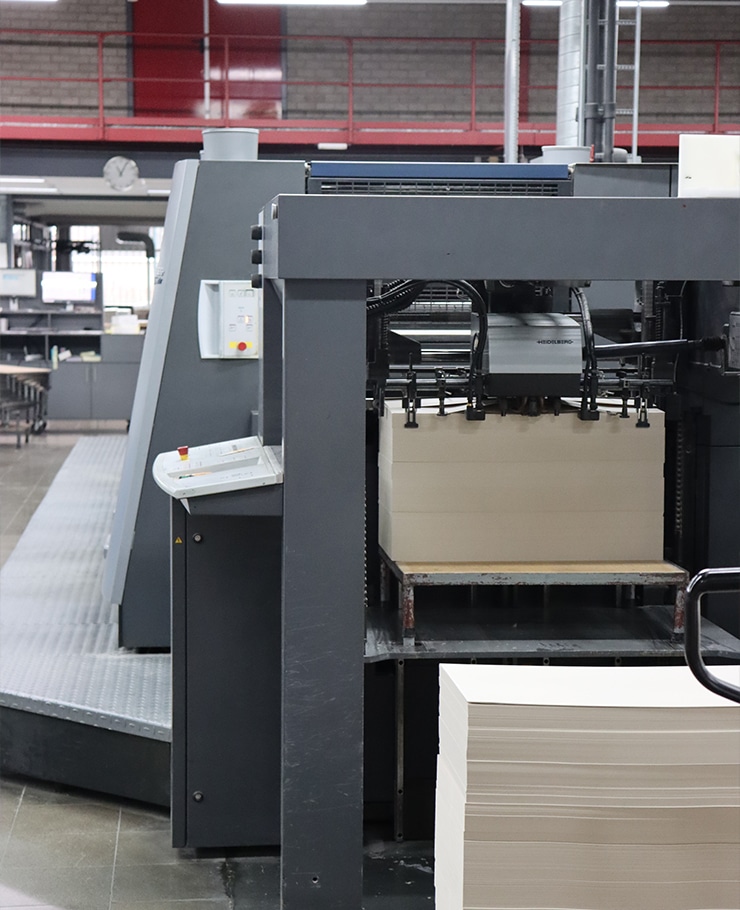

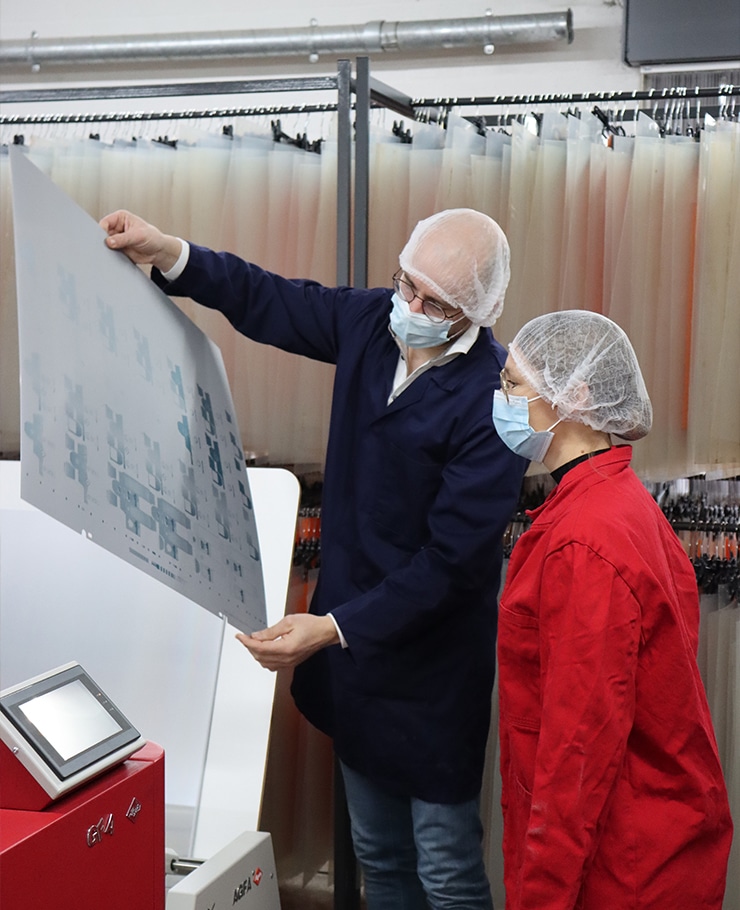

Our label is printed using offset printing, which means that an image is first transferred onto an aluminum plate. This plate is moistened, and the non-image areas absorb the moisture. Then, an oil-based ink is applied. The moisture repels the ink, ensuring that the ink only adheres to the image areas. The ink is then transferred onto a rubber blanket.