The journey at VDL GL plastics begins with the bio-polyethylene pellets. These are delivered in large bags on pallets. The machine that makes the parts of the BE O bottle has a vacuum hose that sucks up the pellets. Inside the machine, the pellets are melted at a high temperature. During the melting process, a very small percentage of natural pigment is added, depending on the color. For our orange BE O bottle, this is only 1.5% to achieve that beautiful orange color.

We like to keep close contact with our partners and producers! This time, we’re heading to Eindhoven, where our BE O bottle producer, VDL GL plastics, is located. Below, we’ll explain exactly how our BE O bottle is made!

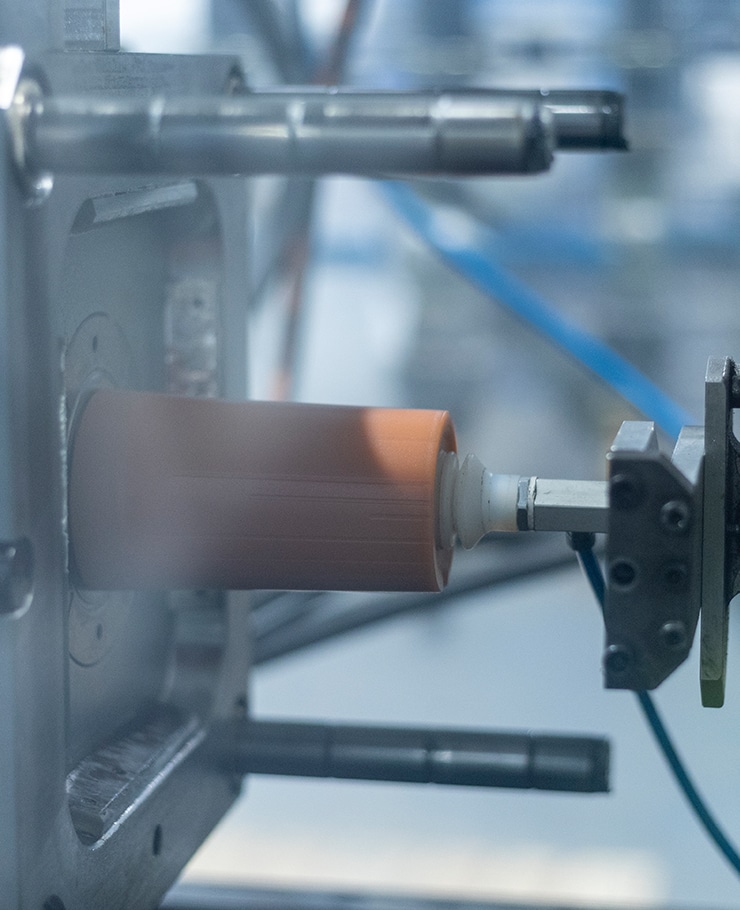

After melting, the liquid material is pressed into a mold. A block (the “man”) is pushed with very high pressure into the mold of a part of the BE O bottle. At the same time, the material is rapidly cooled so it hardens again. At VDL GL plastics, the top and bottom of the BE O bottle are produced, each having its own mold and block that can be inserted into the machine.

A robotic arm with a suction cup moves the newly produced top or bottom of the BE O bottle onto a conveyor belt, where they move in rows of four. The conveyor belt leads to a bin where an employee at VDL GL plastics checks each part and then places them in transport boxes. These transport boxes are then sent to our assembly partner MAAK in Nijmegen. Here, the BE O bottles are assembled by a group of motivated people at the social workplace.

Are you familiar with all our products?

BE O bottle – Orange Clivia

€16,95BE O bottle – Blue Begonia

€16,95BE O bottle – Jade Green

€16,95BE O bottle – Amethist Purple

€16,95